Product Details

Introduction

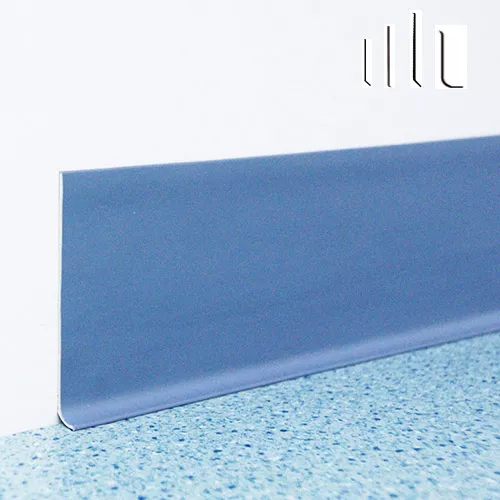

PVC welding rods could prevent water and dust from penetrating the joints and to prevent the growth of bacteria. The rods will also coordinate with different floor materials to gain excellent seam quality, excellent edging and parquet. Each roll comes with a plastic core for easy use and storage.

Features

1. Hot welding for perfect watertightness and hygiene.

2. Superior seam strength.

3. Available in unicolor and multi-color versions (depending on ranges).

4. Designed to match perfectly the flooring color.

5. Multicolor welding rods for HO rolls for invisible welding.

6. Easy to clean and maintain.

Compatible flooring:

Homogeneous vinyls (compact and acoustic)

Heterogeneous vinyls (compact and acoustic)

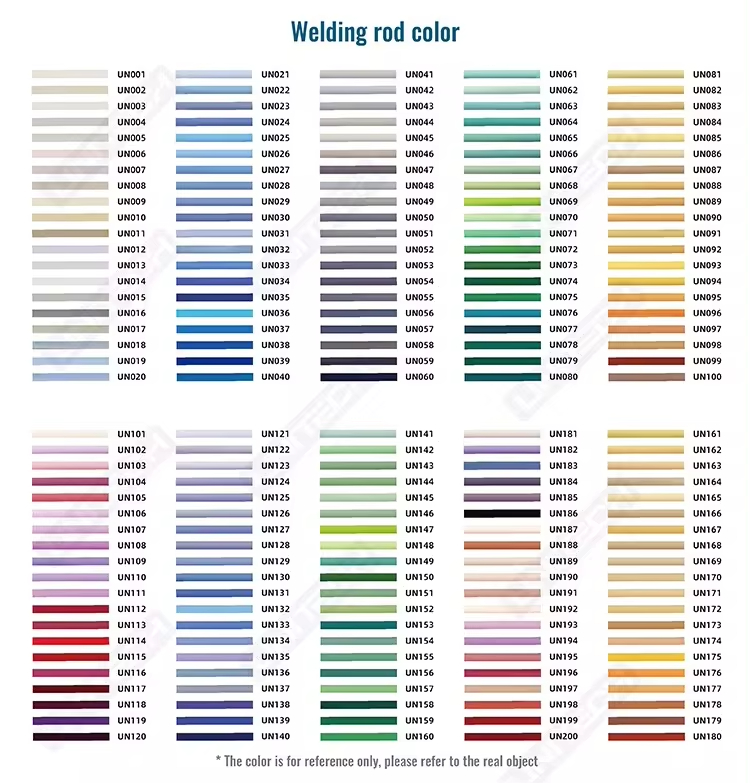

Colors Board

There are many colors to match flooring color, we can create contrast color seem as pattern.

Installation

1. Floorcovering must be welded 24h after the installation.

2. Groove the floor covering to create a gap between both products with 2/3 thickness for compact, till foam for acoustic.

3. Weld the product with an average speed of 2lm/min and a 350-400°C temperature.

4. Rim the overflow of the joint material first with a Quarter moon knife.

5. Trim the joint material with the“Mozart”a second time.